ESS Brothers and Sons' mission is to provide products and services, in an honorable

way, that exceed the expectations and needs of each and every one of our clients.

If we don't have a product in stock, we will find it, and if we can't find it,

we will make it.

ESS Brothers and Sons was establish in 1867 by Joseph Ess and is now in its sixth generation of ownership with Troy and Trent continuing the tradition of excellence established over 148 years ago. From Joseph's establishing a blacksmith and wagon shop to Frank creating a foundry to Edmund and Wallace's vision of supplying municipal castings to Tom's business expansion, the many Ess generations have done what few men do, provide their children with a pathway for a legacy of success.

ESS Brothers and Sons' facilities consist of approximately 35,000 square feet of warehouse, metal fabrication shop, machine shop and office space. The facilities are located on fifteen acres of land with four acres of storage for over 400 different types of municipal castings.

ESS Brothers and Sons' facilities consist of approximately 35,000 square feet of warehouse, metal fabrication shop, machine shop and office space. The facilities are located on fifteen acres of land with four acres of storage for over 400 different types of municipal castings.

Over the years, Ess Brothers and Sons has broadened its metal fabrication product line which now includes ornamental rail, control structures, Arbors, low profile manhole and catch basin frames, Sure-Fit tree and trench grate frames, and tree guards.

ESS Brothers and Sons started to diversify by supplying products designed to prevent inflow and infiltration in manholes, catch basins and joint sections. Consequently, Sealing Systems, Inc. was established in 1995 to focus on the demand for these products across the United States. Sealing Systems developed an internal sealing product called Flex Seal Utility Sealant. In 1996 Paul Ess, a fifth generation Ess, became the General Manager for Sealing Systems. With this move, Ess Brothers and Sons returned to truly being brothers and sons after a lapse of more than seventy-five years. In April of 1999, Sealing Systems Inc. bought the patent rights for an external seal called Infi-Shield. Sealing Systems made some design improvements on the Infi-Shield external seal and also expanded the number of sizes of seals available.

During the 1980's, Ess Brothers and Sons' sales were escalating and the company was in need of more space so that they could fully supply the increasing demand for castings. The frontier village where Joseph established ESS Brothers and Sons no longer existed. The old foundry was in the heart of Chaska and no space for expansion was available. So the fifth generation, Tom, decided to look elsewhere. Tom's goal was to relocate to a place which was within fifteen minutes of a major freeway. In the fall of 1988, he found what he was looking for, 67 acres of land located on Highway 55 in Corcoran, Minnesota. This land purchase sealed the fate for the original old foundry building which through the test of time for more than 100 years. It was a somber spring day in 1990 when this building with so much history was purchased and demolished by the city of Chaska.

The ESS legacy started in 1852, Michael Ess left Bavaria, Germany in hopes of finding a better life in the United States of America. Accompanying him were three of his sons, one named Joseph who was only fourteen years old. In 1854, their long journey was finally complete and they settled in the frontier village now known as Chaska, Minnesota. Joseph and his brother Frank both wanted to find work and learn a trade so that they could make a living without their father. So within a year of reaching Minnesota, they both took a trek to Black River Falls, Wisconsin which is where their older sister lived. In Black River Falls, Joseph learned the trade that would help him successfully develop not only his future but also the future of five more generations by establishing Ess Brothers and Sons, Inc.

Joseph obtained a job at a local foundry in Black River Falls. He learned a great deal about the foundry business, including what not to do. After a years worth of time working at the foundry, the foundry ceased operations. The foundry was unsuccessful in casting iron because the furnace would run only an hour at a time. The coke, which is a petroleum product known for emitting an extremely hot temperature when burned, used in the melting of the metal was never really good. For this reason, the company dissolved with severe losses.

After the closing of the foundry, Joseph and his brother Frank decided to return to

their parents' home in Chaska, Minnesota. It was November and traveling could be

difficult but they had saved enough money to go to St. Paul in style, on a steamboat.

The ride cost them all but ten cents of the money they had saved but it would be worth

the cost to safely return to Minnesota. Because too much ice was on the Mississippi

river, the steamboat was unable to travel any farther north than Winona, Minnesota.

To their dismay, Joseph and Frank returned penniless to Black River Falls, once

again to stay with their older sister.

After the closing of the foundry, Joseph and his brother Frank decided to return to

their parents' home in Chaska, Minnesota. It was November and traveling could be

difficult but they had saved enough money to go to St. Paul in style, on a steamboat.

The ride cost them all but ten cents of the money they had saved but it would be worth

the cost to safely return to Minnesota. Because too much ice was on the Mississippi

river, the steamboat was unable to travel any farther north than Winona, Minnesota.

To their dismay, Joseph and Frank returned penniless to Black River Falls, once

again to stay with their older sister.

Joseph Ess started working for another foundry. It took him a year to save enough money to return home to Chaska, Minnesota. Joseph saved three dollars and was ready to again take the journey home but this time on foot and with a friend from the foundry. An adventurous journey ensued; the long daytime hikes were followed by nights sleeping in the forest, and nights getting chased by farmers because they tried to sleep on their property or to the occasional night being able to sleep indoors on the dirty floor of a saloon.

Joseph finally returned to Chaska, Minnesota, but his stay did not last very long for our great nation was suffering. This suffering was the Civil War and Joseph chose to enlist in the Grand Army of the Republic. He was a Private in Company D of the Union Army and served three years of hard service in the South. He fought in Alabama, where the engagements were some of the last of the war. His regiment was then sent north at the close of the war and Joseph was honorably discharged on August 8, 1865.

Finally, Joseph was able to return to Chaska, Minnesota to begin the business known today as Ess Brothers and Sons, Inc. A newspaper advertisement from October 6, 1866 states "Joseph Ess has also erected a good size wagon shop opposite the American House, where he will turn out No. 1 wagons." Joseph was a blacksmith who made not only wagons, but also buggies and sleighs, about 30 to 40 a year.

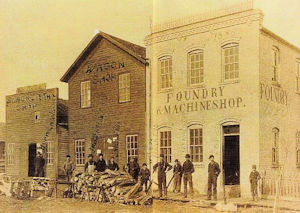

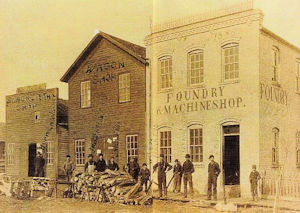

In the 1870's, Joseph decided to branch out into the farm machinery business. He began by repairing equipment, but then a problem arose with the supply of parts. Joseph was unable to buy the necessary iron parts, so he started making them. The knowledge he gained as a young man at the foundries in Black River Falls, Wisconsin was now being fully utilized. In 1880, Joseph started a foundry to make cast iron parts and he named the company Chaska Foundry and Machine Shop.

By the 1880's, there were eleven brickyards in the Chaska area and Joseph realized that a demand for repairing brick making machines existed. The demand was high, actually so high that together, many brickyard owners tried to persuade Joseph to actually convert his foundry for brick making repairs. Joseph did convert his foundry but rather than simply repair the machines, he developed an entirely new machine. Joseph's son, Frank, was the chief designer of the machine which went by the brand name "Nameless" in the Ess catalog. This brick making machine greatly increased a brickyard's capacity; it had the capability to produce over 50,000 bricks a day. Now the Ess Foundry's main business was laying out brick yard production lines from molding to storage and also manufacturing the necessary equipment.

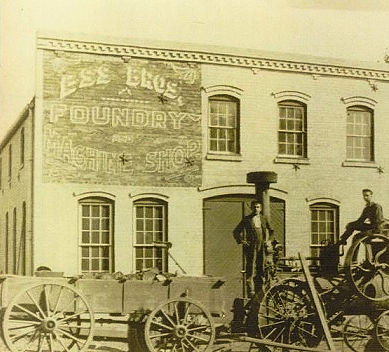

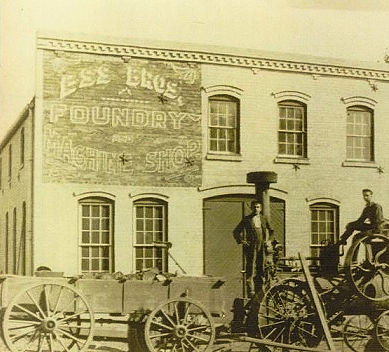

In 1884, to accommodate for their increasing business, a large brick addition was added to the foundry business in Chaska, now going by the name Ess Brothers Chaska Foundry and Machine Shop. In 1896 in order to further expand his foundry, Joseph bought out the Shakopee Foundry which was located in the neighboring city of Shakopee, Minnesota. The Ess foundry did castings of all kinds including plumbers steam and gas fittings, wrought iron pipes, pumps, and brass fittings of every description. Ess Brothers continued to sell and repair wagons, buggies, sleighs and farm machinery.

On April 4, 1901, Joseph sold the business to his two sons, Frank and Fred, who carried on under the name Ess Brothers and Sons. Frank and Fred started working at the family business when they were only fourteen years old, sometime during early 1880's. Frank managed the foundry and he was its designer and molder. Fred ran the wagon and repair shop and was an expert machinist.

The brothers, Frank and Fred, continued to manufacture and repair equipment for brickyards. The foundry produced large cauldrons and kettles which were sold by Montgomery Wards and Sears. With many various uses, Ess Brothers and Sons' kettles were used in households all across the country. The foundry also made iron fencing and iron crosses for cemeteries, both are still seen today in Chaska.

By the 1910's, automobiles became the favored means of transportation. Because people put their cars in storage or on "blocks" for the winter, sleighs were still a good seller and Ess Brothers and Sons still manufactured them. However, the wagon shop business was on the decline; consequently, Ess Brothers and Sons set their sites on the automobile. In 1913, Ess Brothers and Sons established an auto agency and garage across the street from the foundry. Frank's son, Edmund, got out of the grueling foundry work and ran this part of the business. Ess Brothers and Sons was a local agent for the Jackson, Chandler and Maxwell line of automobiles. In 1914, Ess Brothers and Sons even sponsored an industry film on the manufacturing of Maxwell cars.

In 1933, Fred died and his son Oscar became the head machinist. Edmund now became the sales manager and supervisor of the foundry. This same year, Wallace, Edmund's son became the fourth generation of Ess' to work at the foundry. Like his preceding relatives, Wallace began working at the foundry when he was fourteen, but unlike the others, he still remained in school.

Cauldrons were no longer in demand, so Ess Brothers and Sons looked elsewhere for products to manufacture. The foundry continued to make parts for agricultural machines, but they developed into a job supplier, manufacturing parts needed by other companies. They made many parts for things such as tank heaters and brooder stoves. The foundry was a major supplier of tools and hardware for many hardware and department stores such as Sears, Montgomery Wards and Genny Simple Hill.

The foundry continued to flourish until the 1940's. Because of World War II, materials were scarce and it was even difficult to get scrap metal or old cast iron from farms across Minnesota. However, Ess Brothers and Sons decided to manufacture items and parts needed for the war such as steering levers for tanks. Another product was an oil drum stove, many of which were purchased by the government and scattered at Army posts all over the world.

Because Ess Brothers and Sons was manufacturing parts needed for the war, Wallace, the youngest Ess working at the foundry, was not required to enlist in the United States Armed Forces. However, Wallace wanted to serve his nation, so he enlisted in U.S. Air Force on July 22, 1943. He was a Staff Sergeant attached to the 91st Fighter Squadron, 81st Fighter Group in the Asiatic Pacific theatre of operations. Wallace was able to use some of the knowledge he gained at the foundry and machine shop (he built one of the few Gin-Su gin stills in China). He performed the necessary maintenance and repair work on the Air Force's airborne and ground radio equipment. Wallace received two battle stars and after two and half years of service, he returned home to Chaska and to his job at Ess Brothers and Sons.

In 1945, Frank sold his interest in Ess Brothers and Sons to his son, Edmund. In 1951, part of the foundry burned down. Edmund and Wallace were now in charge of rebuilding the foundry and they rose up to the challenge. During the rebuilding, they did not have to lay off any employees because they required the contractor to employ all of Ess Brothers and Sons' employees. The suburban building boom following World War II brought about high demand for municipal castings, and Ess Brothers and Sons tactfully decided to convert and partially rebuild their foundry in order to fulfill this need.

Because Ess Brothers and Sons shifted all their focus on municipal castings, Oscar who was the head machinist decided to sell his share of the company to Wallace. Ess Brothers and Sons' main customers now became municipalities and contractors. In a typical year, Edmund would travel over 15,000 miles submitting bids to municipalities and contractors across Minnesota.

Wallace's oldest son, Thomas became the fifth generation to work at Ess Brothers and Sons at the tender age of eleven. He worked part-time drilling and tapping sleigh shoes. By the time he was fifteen, Tom was driving truck all across Minnesota, and he was even able to get out of school early to go to work.

A year after Tom's return in 1970, Edmund retired and Tom bought Edmund's share of Ess Brothers and Sons.

The foundry was now producing 15 tons of iron per day, equivalent to 65 sets of municipal castings. This was a great improvement from the foundry's initial production of 4 tons a day in the early 1950's. At its peak capacity, the foundry required about thirty workers. Ess Brothers and Sons produced castings mainly for Minnesota, but also for other parts of the United States and even some abroad. A three and a half ton planer table was the largest casting the foundry ever made and it was sent to Africa.

In March of 1972, the Environmental Protection Agency enacted new policies which required that all exhaust fumes must be reduced to acceptable standards by a water cooling system. The cost of modification would be quite expensive, approximately $150,000. Plus, the width of working aisles in the foundry needed to be doubled to meet new federal specifications and this would decrease the foundry's production by 25%. Thus, Ess Brothers and Sons concluded that the best course of action was to close the foundry. Edmund Ess, although retired, stated "the government is not closing us down, but we don't want to gamble with them. We have no guarantee that if we made the changes, it would be acceptable to them later."

The foundry was converted into a warehouse; however, some items were still needed such as the boring machine and drill press. Ess Brothers and Sons sole focus became the sales and distribution of municipal castings. By not having to worry about the manufacturing side of business, Ess Brothers and Sons could provide the best customer service possible.

In 1981, Wallace retired and Tom bought his share of the company. Tom now had sole ownership of Ess Brothers and Sons, something that only existed when Joseph started the company over 100 years ago. Judy Ess, Tom's wife, took over Wallace's job of doing all the bookkeeping, quarterly taxes, doing monthly statements, answering the phone and taking orders. Being the first women to ever work at Ess Brothers and Sons, Judy even delivered castings to customers.

In the early 1980's Tom's two sons, Troy and Trent, began working with the company. In 2003 Tom retired and Troy and Trent bought out Tom's share, to become the sixth generation of ownership at Ess Brothers and Sons.

ESS Brothers and Sons was establish in 1867 by Joseph Ess and is now in its sixth generation of ownership with Troy and Trent continuing the tradition of excellence established over 148 years ago. From Joseph's establishing a blacksmith and wagon shop to Frank creating a foundry to Edmund and Wallace's vision of supplying municipal castings to Tom's business expansion, the many Ess generations have done what few men do, provide their children with a pathway for a legacy of success.

ESS Brothers and Sons' facilities consist of approximately 35,000 square feet of warehouse, metal fabrication shop, machine shop and office space. The facilities are located on fifteen acres of land with four acres of storage for over 400 different types of municipal castings.

ESS Brothers and Sons' facilities consist of approximately 35,000 square feet of warehouse, metal fabrication shop, machine shop and office space. The facilities are located on fifteen acres of land with four acres of storage for over 400 different types of municipal castings.

Over the years, Ess Brothers and Sons has broadened its metal fabrication product line which now includes ornamental rail, control structures, Arbors, low profile manhole and catch basin frames, Sure-Fit tree and trench grate frames, and tree guards.

ESS Brothers and Sons started to diversify by supplying products designed to prevent inflow and infiltration in manholes, catch basins and joint sections. Consequently, Sealing Systems, Inc. was established in 1995 to focus on the demand for these products across the United States. Sealing Systems developed an internal sealing product called Flex Seal Utility Sealant. In 1996 Paul Ess, a fifth generation Ess, became the General Manager for Sealing Systems. With this move, Ess Brothers and Sons returned to truly being brothers and sons after a lapse of more than seventy-five years. In April of 1999, Sealing Systems Inc. bought the patent rights for an external seal called Infi-Shield. Sealing Systems made some design improvements on the Infi-Shield external seal and also expanded the number of sizes of seals available.

During the 1980's, Ess Brothers and Sons' sales were escalating and the company was in need of more space so that they could fully supply the increasing demand for castings. The frontier village where Joseph established ESS Brothers and Sons no longer existed. The old foundry was in the heart of Chaska and no space for expansion was available. So the fifth generation, Tom, decided to look elsewhere. Tom's goal was to relocate to a place which was within fifteen minutes of a major freeway. In the fall of 1988, he found what he was looking for, 67 acres of land located on Highway 55 in Corcoran, Minnesota. This land purchase sealed the fate for the original old foundry building which through the test of time for more than 100 years. It was a somber spring day in 1990 when this building with so much history was purchased and demolished by the city of Chaska.

The ESS legacy started in 1852, Michael Ess left Bavaria, Germany in hopes of finding a better life in the United States of America. Accompanying him were three of his sons, one named Joseph who was only fourteen years old. In 1854, their long journey was finally complete and they settled in the frontier village now known as Chaska, Minnesota. Joseph and his brother Frank both wanted to find work and learn a trade so that they could make a living without their father. So within a year of reaching Minnesota, they both took a trek to Black River Falls, Wisconsin which is where their older sister lived. In Black River Falls, Joseph learned the trade that would help him successfully develop not only his future but also the future of five more generations by establishing Ess Brothers and Sons, Inc.

Joseph obtained a job at a local foundry in Black River Falls. He learned a great deal about the foundry business, including what not to do. After a years worth of time working at the foundry, the foundry ceased operations. The foundry was unsuccessful in casting iron because the furnace would run only an hour at a time. The coke, which is a petroleum product known for emitting an extremely hot temperature when burned, used in the melting of the metal was never really good. For this reason, the company dissolved with severe losses.

After the closing of the foundry, Joseph and his brother Frank decided to return to

their parents' home in Chaska, Minnesota. It was November and traveling could be

difficult but they had saved enough money to go to St. Paul in style, on a steamboat.

The ride cost them all but ten cents of the money they had saved but it would be worth

the cost to safely return to Minnesota. Because too much ice was on the Mississippi

river, the steamboat was unable to travel any farther north than Winona, Minnesota.

To their dismay, Joseph and Frank returned penniless to Black River Falls, once

again to stay with their older sister.

After the closing of the foundry, Joseph and his brother Frank decided to return to

their parents' home in Chaska, Minnesota. It was November and traveling could be

difficult but they had saved enough money to go to St. Paul in style, on a steamboat.

The ride cost them all but ten cents of the money they had saved but it would be worth

the cost to safely return to Minnesota. Because too much ice was on the Mississippi

river, the steamboat was unable to travel any farther north than Winona, Minnesota.

To their dismay, Joseph and Frank returned penniless to Black River Falls, once

again to stay with their older sister.

Joseph Ess started working for another foundry. It took him a year to save enough money to return home to Chaska, Minnesota. Joseph saved three dollars and was ready to again take the journey home but this time on foot and with a friend from the foundry. An adventurous journey ensued; the long daytime hikes were followed by nights sleeping in the forest, and nights getting chased by farmers because they tried to sleep on their property or to the occasional night being able to sleep indoors on the dirty floor of a saloon.

Joseph finally returned to Chaska, Minnesota, but his stay did not last very long for our great nation was suffering. This suffering was the Civil War and Joseph chose to enlist in the Grand Army of the Republic. He was a Private in Company D of the Union Army and served three years of hard service in the South. He fought in Alabama, where the engagements were some of the last of the war. His regiment was then sent north at the close of the war and Joseph was honorably discharged on August 8, 1865.

Finally, Joseph was able to return to Chaska, Minnesota to begin the business known today as Ess Brothers and Sons, Inc. A newspaper advertisement from October 6, 1866 states "Joseph Ess has also erected a good size wagon shop opposite the American House, where he will turn out No. 1 wagons." Joseph was a blacksmith who made not only wagons, but also buggies and sleighs, about 30 to 40 a year.

In the 1870's, Joseph decided to branch out into the farm machinery business. He began by repairing equipment, but then a problem arose with the supply of parts. Joseph was unable to buy the necessary iron parts, so he started making them. The knowledge he gained as a young man at the foundries in Black River Falls, Wisconsin was now being fully utilized. In 1880, Joseph started a foundry to make cast iron parts and he named the company Chaska Foundry and Machine Shop.

By the 1880's, there were eleven brickyards in the Chaska area and Joseph realized that a demand for repairing brick making machines existed. The demand was high, actually so high that together, many brickyard owners tried to persuade Joseph to actually convert his foundry for brick making repairs. Joseph did convert his foundry but rather than simply repair the machines, he developed an entirely new machine. Joseph's son, Frank, was the chief designer of the machine which went by the brand name "Nameless" in the Ess catalog. This brick making machine greatly increased a brickyard's capacity; it had the capability to produce over 50,000 bricks a day. Now the Ess Foundry's main business was laying out brick yard production lines from molding to storage and also manufacturing the necessary equipment.

In 1884, to accommodate for their increasing business, a large brick addition was added to the foundry business in Chaska, now going by the name Ess Brothers Chaska Foundry and Machine Shop. In 1896 in order to further expand his foundry, Joseph bought out the Shakopee Foundry which was located in the neighboring city of Shakopee, Minnesota. The Ess foundry did castings of all kinds including plumbers steam and gas fittings, wrought iron pipes, pumps, and brass fittings of every description. Ess Brothers continued to sell and repair wagons, buggies, sleighs and farm machinery.

On April 4, 1901, Joseph sold the business to his two sons, Frank and Fred, who carried on under the name Ess Brothers and Sons. Frank and Fred started working at the family business when they were only fourteen years old, sometime during early 1880's. Frank managed the foundry and he was its designer and molder. Fred ran the wagon and repair shop and was an expert machinist.

The brothers, Frank and Fred, continued to manufacture and repair equipment for brickyards. The foundry produced large cauldrons and kettles which were sold by Montgomery Wards and Sears. With many various uses, Ess Brothers and Sons' kettles were used in households all across the country. The foundry also made iron fencing and iron crosses for cemeteries, both are still seen today in Chaska.

By the 1910's, automobiles became the favored means of transportation. Because people put their cars in storage or on "blocks" for the winter, sleighs were still a good seller and Ess Brothers and Sons still manufactured them. However, the wagon shop business was on the decline; consequently, Ess Brothers and Sons set their sites on the automobile. In 1913, Ess Brothers and Sons established an auto agency and garage across the street from the foundry. Frank's son, Edmund, got out of the grueling foundry work and ran this part of the business. Ess Brothers and Sons was a local agent for the Jackson, Chandler and Maxwell line of automobiles. In 1914, Ess Brothers and Sons even sponsored an industry film on the manufacturing of Maxwell cars.

In 1933, Fred died and his son Oscar became the head machinist. Edmund now became the sales manager and supervisor of the foundry. This same year, Wallace, Edmund's son became the fourth generation of Ess' to work at the foundry. Like his preceding relatives, Wallace began working at the foundry when he was fourteen, but unlike the others, he still remained in school.

Cauldrons were no longer in demand, so Ess Brothers and Sons looked elsewhere for products to manufacture. The foundry continued to make parts for agricultural machines, but they developed into a job supplier, manufacturing parts needed by other companies. They made many parts for things such as tank heaters and brooder stoves. The foundry was a major supplier of tools and hardware for many hardware and department stores such as Sears, Montgomery Wards and Genny Simple Hill.

The foundry continued to flourish until the 1940's. Because of World War II, materials were scarce and it was even difficult to get scrap metal or old cast iron from farms across Minnesota. However, Ess Brothers and Sons decided to manufacture items and parts needed for the war such as steering levers for tanks. Another product was an oil drum stove, many of which were purchased by the government and scattered at Army posts all over the world.

Because Ess Brothers and Sons was manufacturing parts needed for the war, Wallace, the youngest Ess working at the foundry, was not required to enlist in the United States Armed Forces. However, Wallace wanted to serve his nation, so he enlisted in U.S. Air Force on July 22, 1943. He was a Staff Sergeant attached to the 91st Fighter Squadron, 81st Fighter Group in the Asiatic Pacific theatre of operations. Wallace was able to use some of the knowledge he gained at the foundry and machine shop (he built one of the few Gin-Su gin stills in China). He performed the necessary maintenance and repair work on the Air Force's airborne and ground radio equipment. Wallace received two battle stars and after two and half years of service, he returned home to Chaska and to his job at Ess Brothers and Sons.

In 1945, Frank sold his interest in Ess Brothers and Sons to his son, Edmund. In 1951, part of the foundry burned down. Edmund and Wallace were now in charge of rebuilding the foundry and they rose up to the challenge. During the rebuilding, they did not have to lay off any employees because they required the contractor to employ all of Ess Brothers and Sons' employees. The suburban building boom following World War II brought about high demand for municipal castings, and Ess Brothers and Sons tactfully decided to convert and partially rebuild their foundry in order to fulfill this need.

Because Ess Brothers and Sons shifted all their focus on municipal castings, Oscar who was the head machinist decided to sell his share of the company to Wallace. Ess Brothers and Sons' main customers now became municipalities and contractors. In a typical year, Edmund would travel over 15,000 miles submitting bids to municipalities and contractors across Minnesota.

Wallace's oldest son, Thomas became the fifth generation to work at Ess Brothers and Sons at the tender age of eleven. He worked part-time drilling and tapping sleigh shoes. By the time he was fifteen, Tom was driving truck all across Minnesota, and he was even able to get out of school early to go to work.

A year after Tom's return in 1970, Edmund retired and Tom bought Edmund's share of Ess Brothers and Sons.

The foundry was now producing 15 tons of iron per day, equivalent to 65 sets of municipal castings. This was a great improvement from the foundry's initial production of 4 tons a day in the early 1950's. At its peak capacity, the foundry required about thirty workers. Ess Brothers and Sons produced castings mainly for Minnesota, but also for other parts of the United States and even some abroad. A three and a half ton planer table was the largest casting the foundry ever made and it was sent to Africa.

In March of 1972, the Environmental Protection Agency enacted new policies which required that all exhaust fumes must be reduced to acceptable standards by a water cooling system. The cost of modification would be quite expensive, approximately $150,000. Plus, the width of working aisles in the foundry needed to be doubled to meet new federal specifications and this would decrease the foundry's production by 25%. Thus, Ess Brothers and Sons concluded that the best course of action was to close the foundry. Edmund Ess, although retired, stated "the government is not closing us down, but we don't want to gamble with them. We have no guarantee that if we made the changes, it would be acceptable to them later."

The foundry was converted into a warehouse; however, some items were still needed such as the boring machine and drill press. Ess Brothers and Sons sole focus became the sales and distribution of municipal castings. By not having to worry about the manufacturing side of business, Ess Brothers and Sons could provide the best customer service possible.

In 1981, Wallace retired and Tom bought his share of the company. Tom now had sole ownership of Ess Brothers and Sons, something that only existed when Joseph started the company over 100 years ago. Judy Ess, Tom's wife, took over Wallace's job of doing all the bookkeeping, quarterly taxes, doing monthly statements, answering the phone and taking orders. Being the first women to ever work at Ess Brothers and Sons, Judy even delivered castings to customers.

In the early 1980's Tom's two sons, Troy and Trent, began working with the company. In 2003 Tom retired and Troy and Trent bought out Tom's share, to become the sixth generation of ownership at Ess Brothers and Sons.